Stepping back from a precarious ledge, my heart pounding, I couldn’t help but feel a wave of relief wash over me. It was then I realized the importance of proper safety measures, especially when working around hazardous openings and holes. This incident, thankfully with no serious consequences, brought to light the critical role that 29 CFR 1910.23 plays in workplace safety.

Image: www.ehss.vt.edu

This regulation, a cornerstone of OSHA guidelines, ensures the protection of workers from potential fall hazards associated with various openings and holes found in industrial and construction settings. It’s not just about safety equipment; it’s about a proactive approach to hazard identification and prevention, safeguarding the well-being of every worker.

Understanding 29 CFR 1910.23

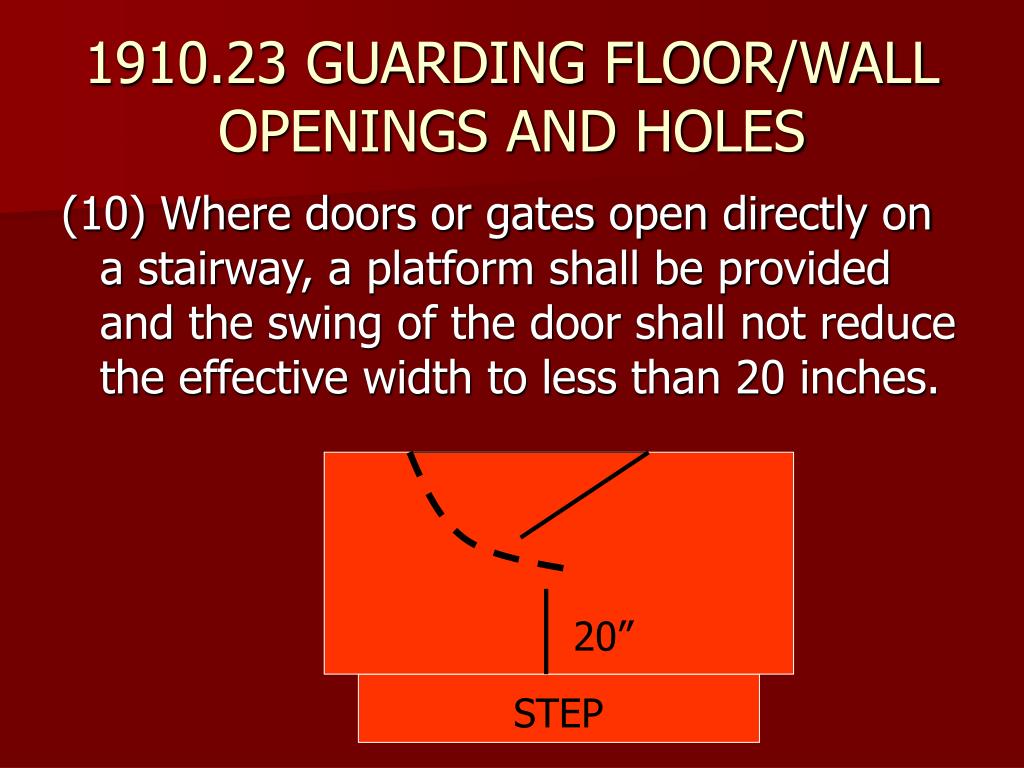

The 29 CFR 1910.23 standard, part of the Occupational Safety and Health Administration (OSHA) General Industry Standards, is dedicated to the safe design, construction, and maintenance of floors, walls, and openings within workplaces. It mandates specific guardrail requirements for various openings and holes, whether they are fixed or movable, to prevent falls and associated injuries.

The purpose of this standard is to minimize fall-related risks by ensuring that all hazardous openings and holes are properly guarded with secure and resilient barriers. These barriers serve as a critical safety net, preventing employees from falling through or into these openings, especially when working at elevated heights or in confined spaces.

The Scope of 29 CFR 1910.23

29 CFR 1910.23 extends its protective umbrella over a broad spectrum of workplace scenarios, covering various types of openings and holes, including:

- Floor Openings: Any opening in a floor, such as a stairwell, elevator shaft, or pit, that poses a fall risk.

- Wall Openings: Gaps in walls, like window openings or vents, that could lead to falls or other injuries.

- Holes: Openings in floors or walls, including access holes, maintenance openings, and other similar gaps.

- Skylights: Unguarded skylights, typically found in roofs, that can lead to serious falls.

Detailed Explanation of 29 CFR 1910.23

29 CFR 1910.23 outlines detailed specifications for guarding these openings and holes, ensuring that they are adequately protected. Let’s delve into the key requirements:

Image: www.slideserve.com

Guardrail Systems

The standard mandates the use of guardrail systems when working near hazardous openings and holes. These systems must meet specific requirements concerning height, strength, and construction:

- Height: The top edge of the guardrail should be at least 42 inches high above walking surfaces, ensuring a secure barrier against falling objects and employees.

- Strength: The guardrail system must be able to withstand a downward force of at least 200 pounds, ensuring its structural integrity and ability to withstand potential impacts.

- Construction: The guardrail system should be constructed with sturdy materials, typically wood, metal, or a combination, and should be properly anchored to the floor or wall for reliable support.

Covers and Other Protective Measures

In certain situations, guardrails alone may not suffice. In such cases, 29 CFR 1910.23 requires the use of alternative protective measures, such as:

- Covers: For openings that are not regularly used, solid covers can be employed to completely seal the opening, eliminating the fall risk.

- Safety Nets: In situations where a fall could result in a significant drop, safety nets can be installed to minimize the impact. These nets must be properly designed and installed to effectively catch a falling person.

- Other Protective Devices: Depending on the specific circumstances, other devices like warning lines, ladders, or personal fall arrest systems may be required to ensure worker safety.

Exceptions and Modifications

While 29 CFR 1910.23 emphasizes the need for proper guarding, it recognizes that certain situations may necessitate exceptions or modifications to the standard requirements. In these cases, employers can apply for a variance, demonstrating that their alternative measures provide a level of safety equivalent to the standard’s provisions.

Trends and Developments

The construction and industrial sectors are constantly evolving, and so are the safety regulations governing them. 29 CFR 1910.23 has been updated and modified over the years to reflect these changes. In recent years, there has been growing emphasis on:

- Fall Protection Training: Increased focus on providing comprehensive fall protection training to workers, covering the use of guardrails, safety nets, and personal fall arrest systems.

- Hazard Recognition: Emphasizing the importance of recognizing fall hazards early in the design and planning stages of construction projects, ensuring proactive safety measures.

- Technology Integration: Leveraging technology to enhance workplace safety, such as using sensors to monitor worker locations and detect fall risks.

Expert Advice and Tips

Ensuring workplace safety is a collaborative effort, requiring knowledge, vigilance, and adherence to regulations. To make it easier, here are some tips and expert advice for implementing 29 CFR 1910.23 in your workplace:

- Regular Inspections: Conduct regular inspections of all floor and wall openings and holes to ensure that guardrails and other protective measures are in good working condition and are properly maintained.

- Engaging Workers: Encourage workers to report any hazards or inadequacies they encounter, promoting a culture of safety in the workplace.

- Updated Training: Provide ongoing training to workers on proper fall protection techniques and the use of safeguarding equipment.

- Safety Committees: Establish safety committees to review potential hazards, recommend improvements, and ensure compliance with 29 CFR 1910.23.

Remember, adhering to 29 CFR 1910.23 is not just about compliance; it’s about ensuring the safety and well-being of your workforce. By following the outlined guidelines and cultivating a strong safety culture, you can minimize the risk of falls and protect your valuable employees from serious injuries.

FAQ on 29 CFR 1910.23

Here are some frequently asked questions about 29 CFR 1910.23:

Q: What is the purpose of guardrails around openings?

A: Guardrails are designed to prevent workers from falling through or into openings, creating a physical barrier that significantly reduces the risk of falls.

Q: Are there any exceptions to the guardrail requirements?

A: Yes, the standard allows for exceptions in certain circumstances, such as when the opening is regularly used for access or when alternative protective measures provide an equivalent level of safety.

Q: Can I use a safety net instead of guardrails?

A: Yes, safety nets are an acceptable alternative to guardrails when a fall could result in a significant drop. However, they must be properly designed, installed, and maintained to effectively catch a falling person.

Q: What are some common violations of 29 CFR 1910.23?

A: Common violations include the lack of guardrails, inadequate guardrail height, insufficient structural strength of guardrails, and incomplete or improper installation of protective measures.

Q: What are the consequences of violating 29 CFR 1910.23?

A: Violations can result in fines, citations, and even potential legal action. It’s crucial to ensure compliance with the standard to avoid penalties and protect your workforce.

29 Cfr 1910.23 Guarding Floor And Wall Openings And Holes

Conclusion

29 CFR 1910.23: Guarded Floor and Wall Openings and Holes is a vital component of workplace safety. By implementing the specific guidelines and embracing a proactive approach to hazard identification and prevention, employers can protect their workers and create a safer environment. It’s not just about meeting a regulation, but about safeguarding lives.

Are you interested in learning more about workplace safety and 29 CFR 1910.23? Let us know in the comments below!

/GettyImages-173599369-58ad68f83df78c345b829dfc.jpg?w=740&resize=740,414&ssl=1)