Picture this: you’re working on your car, a quick tire change, and your floor jack inexplicably loses its handle. Panic sets in. You’ve got a car in the air, and you’re stuck without the means to lower it safely. What do you do? Well, there are some tried-and-true options, but before you attempt any of them, remember, safety should always be your number one priority. Let’s navigate this tricky situation together, ensuring that both you and your car remain unscathed.

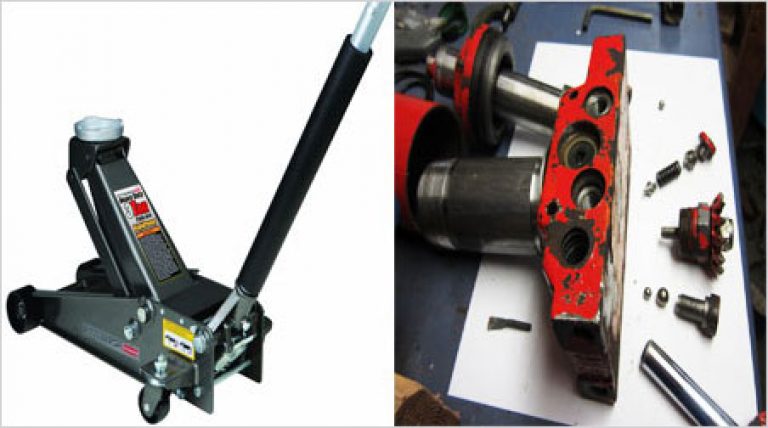

Image: bestfloorjackguide.com

So, what’s the best course of action when you find yourself in this predicament? The most important thing to remember is that you should never attempt to lower a floor jack without the handle if it’s carrying a heavy load, like a car. You’ll risk serious damage to your car and create a dangerous situation for yourself. We’ll discuss lowering a jack with a lighter load, like a motorcycle or a set of wheels, but the safest route is always to call for professional assistance when an automotive jack is involved.

Lowering a Floor Jack Without the Handle: Alternatives

When you find yourself handle-less, it’s time to get creative. The good news is that, in some cases, you can manually lower a floor jack without causing any damage. Let’s explore the different methods at your disposal:

Method 1: Leveraging the Jack’s Release Mechanism

Most floor jacks feature a release lever located directly below the lifting handle. While this lever usually aids in lowering the jack, it can often act as an alternative in the absence of a handle. Here’s how it works:

- Locate the Release Lever: Look for the lever directly below where the handle connects to the jack, usually a small metal bar or knob.

- Engage the Release Mechanism: This lever typically depresses a valve that allows fluid to escape the jack’s hydraulic system, causing it to lower.

- Apply Pressure: Using a large wrench or a sturdy piece of wood against the lever, forcefully push or pull on it. The jack should gradually lower. Be cautious as applying too much force can damage the jack.

- Monitor the Lowering: Watch the jack carefully as it lowers. If it stops or becomes difficult to move, don’t forcefully press on the lever. Seek alternative methods to complete the lowering process.

Method 2: Utilizing a Wrench or Prying Tool

This method requires a bit more caution and is best suited for lighter loads, but it can be a lifesaver in a pinch:

- Locate the Release Valve: Identify the valve on the jack’s cylinder that controls the release of hydraulic fluid. It’s usually a small metal knob or bolt.

- Choose the Right Tool: You’ll need a wrench or a sturdy pry bar that fits snugly against the valve’s edge. If you use a wrench, ensure that it doesn’t slip off, causing potential damage to the jack.

- Apply Gentle Force: Gradually turn the wrench or pry bar in a direction that will release the valve, allowing the hydraulic fluid to escape.

- Monitor and Adjust: As the load lowers, keep a close eye on the progress. Adjust the pressure you apply to the wrench or pry bar as needed to ensure a smooth and controlled descent.

Image: www.finepowertools.com

Method 3: The “Wooden Block” Trick For Jacks with a Screw Mechanism

Some floor jacks use a screw mechanism for lifting instead of hydraulics. If your jack has this type, the handle serves to turn the screw. Here’s how you can lower it without the handle:

- Find a Solid Block: You’ll need a piece of wood or a strong material that can act as a wedge.

- Insert the Block: Gently insert the block between the jack’s base and the ground, creating a wedge. The block will prevent the jack from rising further.

- Loosen the Screw: Using a wrench or another tool that fits the screw, slowly turn it counter-clockwise. The jack will gradually lower as the screw retracts.

- Carefully Monitor: As the jack lowers, be extremely cautious and monitor its movement closely. If you feel resistance or notice the block shifting, stop immediately to avoid damaging the jack.

Safety First: Essential Precautions

Before attempting any of these methods, it’s crucial to understand the risks involved and take necessary precautions.

- Never attempt to lower a jack under load without a handle: Only attempt these methods on lighter loads where there’s no risk of the jack failing or causing injury.

- Use a sturdy work surface: Ensure the jack is placed on a firm, level surface that can support the load without buckling.

- Wear safety goggles: Protecting your eyes from falling debris is always a good idea when working with mechanical equipment.

- Don’t rush the process: Lower the jack slowly and steadily to avoid sudden drops that could damage your vehicle or lead to injury.

- Have backup tools available: In case these methods don’t work, have some backup tools ready in case you need extra leverage or need to make adjustments to the jack.

- If in doubt, call a professional: If you’re unsure about any of these methods or if you have a heavy load, call a mechanic or roadside assistance to help you safely lower the jack.

Frequently Asked Questions

Q1. What should I do if my floor jack’s handle is broken?

If your handle is broken, it’s important to replace it as soon as possible. There are many online stores that sell floor jack handles, or you can check with your local auto parts store for a replacement. Avoid using damaged or broken floor jacks – this puts you and your vehicle at risk.

Q2. Can I use a makeshift lever to lower the jack?

While it may seem appealing, using a makeshift lever is generally not recommended. This could lead to the lever slipping, causing serious damage to your vehicle or injury to yourself. Instead, follow the safe methods outlined above or consult a professional.

Q3. How do I prevent my floor jack handle from breaking in the future?

To avoid broken handles, inspect your floor jack regularly. Ensure the handle is securely attached and inspect the mechanism for any signs of wear or damage. Also, avoid over-extending the jack and over-stressing its capacity.

Q4. Why is it so dangerous to lower a jack carrying heavy weight without the handle?

Lowering a jack under load without a handle increases the risk of uncontrolled lowering, potential damage to your vehicle, and even serious injury. The jack could fail, drop the vehicle, and create a hazardous situation. Always prioritize safety by securing the load with appropriate stands before attempting to lower the jack.

How To Lower A Floor Jack Without The Handle

Conclusion

Finding yourself without a floor jack handle can be a stressful situation. However, by using the methods discussed in this guide and prioritizing safety, you can safely lower a jack without the handle in most cases. Remember, knowledge is power, and by understanding the proper techniques and taking precautions, you can tackle this challenge head-on and confidently get your project back on track. Are you ready to tackle your next automotive project with a new level of confidence?

/GettyImages-173599369-58ad68f83df78c345b829dfc.jpg?w=740&resize=740,414&ssl=1)