Imagine a bustling warehouse, filled to the brim with goods stacked high, ready to be shipped out to eager customers. The air is thick with the hum of forklifts maneuvering through narrow aisles, their drivers expertly navigating the maze of towering metal shelves. Suddenly, there’s a loud crash, a sickening shudder, and a cascading wave of boxes falls onto the floor. What caused this disaster? A pallet rack system that wasn’t properly secured.

Image: allracksolutions.com

This scenario might seem dramatic, but it highlights a crucial safety concern in warehouse operations. The question of whether to bolt pallet racks to the floor is not just about aesthetics or convenience; it’s about protecting workers, preventing damage to equipment and inventory, and ensuring the overall stability of your warehouse. Understanding the factors that influence this decision is critical for ensuring a safe and efficient work environment.

Why Bolt Pallet Racks to the Floor?

Bolting pallet racks to the floor is a proactive measure taken to prevent a range of potential problems. It primarily addresses these critical safety concerns:

1. Preventing Tip-Overs and Collapses

Pallet racking systems, especially when loaded with heavy goods, can be prone to tipping over. This is particularly true in areas with high traffic, uneven floors, or vibrations from machinery. Bolting the racks to the floor creates a secure anchor, significantly reducing the risk of these catastrophic events, which can lead to injuries, property damage, and costly downtime.

2. Minimizing Damage to Inventory and Equipment

A falling pallet rack can lead to the destruction of valuable inventory and potentially damage forklifts and other machinery. Securing the racks to the floor helps to prevent these costly losses, protecting your investment and maintaining operational efficiency.

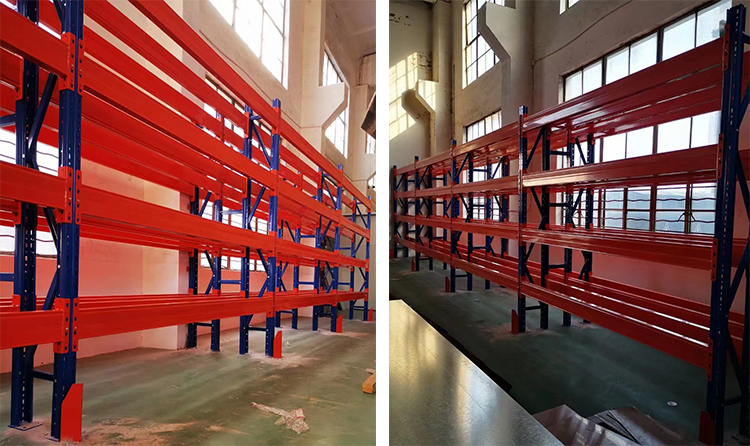

Image: www.lyracking.com

3. Protecting Workers from Injuries

Collapsing pallet racks can cause serious injuries to workers who are in close proximity. Injuries can range from minor cuts and bruises to broken bones and even fatalities. Bolting the racks to the floor reduces the likelihood of these accidents, creating a safer working environment for everyone.

When Is Bolting Absolutely Necessary?

While bolting pallet racks to the floor is generally recommended as a best practice, there are situations where it becomes mandatory, often dictated by local building codes and regulations. These situations typically include:

1. High-Volume, High-Density Storage

Warehouses dealing with large volumes of heavy goods or using high-density storage methods, like double-deep racking, need to take extra precautions. The increased load and weight distribution in such systems create a higher risk of instability, making bolting essential.

2. Seismic Zones

Areas prone to earthquakes or other seismic activity require extra measures to ensure structural integrity. Bolting pallet racks to the floor helps to prevent potential collapse during an earthquake, mitigating damage and ensuring safety.

3. High-Traffic Areas

Warehouses with heavy pedestrian foot traffic or constant forklift movement necessitate bolting to prevent accidental collisions and racking instability. The added security contributes to a safer work environment.

How Bolting Affects Your Warehouse

Bolting pallet racks to the floor comes with both advantages and potential drawbacks that necessitate careful consideration. Here’s a breakdown of the key aspects:

Advantages:

- Enhanced Safety: Reduces the risk of tip-overs, collapses, and injuries, creating a safer working environment for employees.

- Reduced Damage: Protects inventory and equipment from damage caused by accidents or instability.

- Improved Efficiency: Minimal downtime due to accidents, allowing for uninterrupted operations and faster turnaround times.

- Compliance with Regulations: Meets building codes and safety standards, minimizing legal and regulatory risks.

Disadvantages:

- Increased Installation Cost: The process of bolting racks to the floor requires specialized equipment and skilled labor, adding to installation costs.

- Limited Flexibility: Once bolted, moving or reconfiguring the racking system becomes more challenging and time-consuming, potentially impacting layout changes and future warehouse expansions.

- Floor Damage: Drilling into the concrete floor can cause temporary damage, requiring repairs after the installation is complete.

Alternatives to Bolting:

While bolting is the most common and effective method for securing pallet racks, alternative options exist for specific situations:

1. Heavy-Duty Base Plates

These plates are designed to distribute the weight of the rack system over a larger area, minimizing the risk of tipping. They are often used in conjunction with specialized bolts that create a strong connection without drilling into the floor.

2. Floor Anchors

Floor anchors work by embedding metal plates into the floor, creating a secure point of attachment for the rack system. They offer a more flexible alternative to bolting, allowing for easier relocation of the racking system.

3. Epoxy Resin

Epoxy resin is a strong adhesive that can be used to secure the base of the pallet rack to the floor. While not as robust as bolting, it provides a solid attachment for lighter-duty applications.

Assessing Your Needs:

The decision of whether or not to bolt pallet racks to the floor requires a careful assessment of your individual needs, considering factors like:

1. Weight Capacity:

The weight of the goods you store, combined with the height and configuration of your racking system, will influence the level of security required.

2. Traffic:

The amount of pedestrian and forklift traffic in your warehouse plays a critical role in determining the necessary safety measures.

3. Building Code Requirements:

Understanding local building codes and regulations regarding pallet rack installation is crucial to ensure compliance and safety.

4. Budget:

Bolting racks to the floor requires upfront investment in materials, specialized equipment, and labor. Weighing the potential costs and benefits against the budget is essential.

5. Flexibility Requirements:

If you anticipate needing to move or reconfigure your racking system in the future, you might consider alternative securing methods that allow for greater mobility.

Do Pallet Racks Need To Be Bolted To The Floor

Conclusion:

The decision of whether to bolt pallet racks to the floor is a significant one, with implications for safety, efficiency, and long-term cost considerations. While bolting offers the highest level of security and stability, it’s not always necessary or feasible. By accurately assessing your needs, weighing the costs and benefits, and exploring potential alternatives, you can make an informed decision that prioritizes both safety and warehouse functionality. Remember, choosing the right securing method for your pallet racks is an investment in the long-term sustainability and success of your warehouse operation.

/GettyImages-173599369-58ad68f83df78c345b829dfc.jpg?w=740&resize=740,414&ssl=1)